Thickness gauges

Ultrasonic thickness gauge UT-1M

The portable ultrasonic thickness gauge UT-1M, for operative non-destructive testing of the thickness, works on the principle of ultrasounds’ propagation time measurement in the analysed material. The pulsations generator produces high frequency electrical pulses which agitate the probe. It converts the electrical signals into elastic (mechanical) vibrations – sound waves. These waves spread from the input surface to the reflective surface (bottom) and, once turned back, they are collected and converted into the electrical signal via PET. After that the device calculates the thickness of the tested object.

Features:

• Wide range of measurable thicknesses.

• Convenience and ease in operation.

• Select the type of probe through single button.

• Preset velocity of ultrasounds.

• Compensation of probe delay.

• Mapping the presence of acoustic coupling on the graphic display.

• Fixation of the last measurement result in the removal of the transducer surface.

• Ideal for products made of various metals, alloys and other materials; glass, plastic, composite and other products from non-metallic materials; the walls of the tanks, pipes, casing parts, sheets, overhead, and other structures, including the corroded surfaces, pitted, with scum, etc.

Standard supply:

• Electronic unit

• Transducer (probe), 1 pc

• 2 AAA batteries

• Charger

• Cable

• Operating manual

• Carrying case

Optional accessories:

• Couplant

• UT-probes

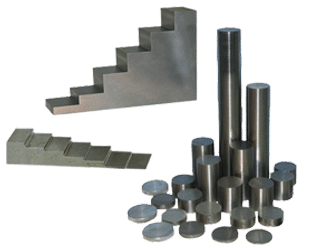

• Reference blocks

Ultrasonic thickness gauge UT-1M-IP

Ultrasonic thickness gauge UT-1M-IP is a special version of ultrasonic thickness gauge, it is designed to measure the thickness of various materials and products for one-way access in difficult climatic conditions – in dusty rooms, in high humidity, in the rain – when the use of a conventional ultrasonic thickness gauge is impossible.

It is used to control the thickness of materials such as glass, metals and alloys, polymers, plastic and many others. Objects can be pipes, rolled products, structures, products and parts for various purposes and shapes.

Advantages:

• Unique protection from dust and moisture. By default the device comes with a degree of dust-moisture protection IP65. This protection degree can be increased up to IP67 (submerged in water) at order.

• Unprecedented autonomy of the device – increased up to 200 hours continuous operation time of the thickness gauge.

• Special rubber lining on the side surfaces of the casing facilitates the convenient retention of the thickness gauge in the user’s hand.

• Device has light weight and dimensions, in comparison with similar protected thickness gauges.

• Saved data can be transmit to PC.

• Material selection and automatic setting of ultrasound velocity.

• Large graphic display of high contrast and backlight.

• Display of measured thickness in mm and inches.

• Convenient menu in the device.

• Wide choice of UT probes with preset settings in the device.

• Modes of statistical processing of measurements.

• Ability to restore factory calibrations.

• Ability to adjust all parameters of the acoustic path.

• Ability of further adjusting the user gain directly from the measurement mode.

• Wide range of testing.

• Mode of audible and visual alarm when leaving the established ranges.

Optional accessories:

• UT-1M-IP (Lab) – with wireless connection to Android gadgets via NOVOTEST Lab App

• UT-1M-IP – basic model

• Couplant

• Calibration certificate issued by the Independent metrology laboratory

• Certificate of origin issued by the Chamber of Commerce and Industry

• Step wedge calibration blocks

• UT-probes:

– 1.25 MHz probe for thickness gauge 20/2

– 2.0 MHz probe for thickness gauge 20/2

– 2.5 MHz probe for thickness gauge 12/2

– 5 MHz probe for thickness gauge 10/2

– 10 MHz probe for thickness gauge 6/2

– 10 MHz probe for thickness gauge 3×2

– 5 MHz probe for thickness gauge (echo-echo) 10/2

– 10 MHz probe for thickness gauge (echo-echo) 6/2

– 5 MHz high-temperature probe for thickness gauge 10/2

– 5 MHz probe for thickness gauge (echo-echo) 10/2, underwater, 10 m cable

– 5 MHz probe for thickness gauge (echo-echo) 10/2, underwater, 20 m cable

– 5 MHz probe for thickness gauge (echo-echo) 10/2, underwater, 30 m cable

Standard supply:

• Electronic unit

• Transducer (probe) – 1 pc for choice (2.5 MHz, 5 MHz or 10 MHz)

• AA batteries – 3 pcs

• Charger

• Cable for PC

• Online PC software

• NOVOTEST Lab App for Android gadgets (for UT-1M-IP (Lab) only)

• Operating manual

• Carrying case