Roughness testers

Roughness measurement can be very important on some parts; it can make piece’s operating features change in a very significant way. These instruments are recognised to be efficient in hard-to-reach points’ measurement.

Non-destructive testing instrument used for measuring surface roughness. The possibility to measure different parameters and to set various measurement profiles makes it a highly professional device, suitable to operate both in production and in laboratory. The roughness tester is commonly employed for quality control activities and to check incoming and outgoing goods.

iSurfa-100 Surface roughness tester

The portable roughness tester is a new generation of portable surface roughness tester introduced by our company. It has the characteristics of high measurement accuracy, wide measurement range, simple operation, easy portability and stable operation. It can be widely used in the detection of various metal and non-metal processing surfaces. It is a pocket instrument integrated with a host and a sensor. It has the characteristics of hand-held, and is more suitable for use in the production site.

Features:

• The exterior is designed by drawing aluminium die, which is durable and has remarkable anti-electromagnetic interference ability, and conforms to the new trend of design today.

• Low-power consumption ARM processor is used for data processing and calculation, which improves the speed of measurement and calculation greatly.

• The display LCD adopts 1.14 inches IPS TFT, with high brightness and no dead visual angle, which is suitable for various occasions.

• With a AA battery, it can work for a long time.

• Equipped with Bluetooth adapter, it can communicate with Bluetooth devices such as smart phones.

• 500 groups of measurement data can be stored.

• Monitor and display the power of battery in real time, timely remind users to charge and with charging progress prompt.

• The automatic shutdown function and low-power software and hardware design make the instrument work for a long time, which is suitable for all kinds of field use.

• The sensor probe has a protective door, which effectively protects the sensor probe and ensures the accuracy of measurement.

Technical data:

| Parameters (μm) | Ra - Rz - Rq - Rt |

| Travel length | 5.6 mm |

| Sample length | 0.25 mm - 0.80 mm - 2.50 mm |

| Evaluation length | 1.25 mm - 4.0 mm |

| Measuring range | Ra, Rq: 0.05 ~ 10.0 μm - Rz, Rt: 0.1 ~ 50 μm |

| Display error | ±10% |

| Display variability | <12% |

| Stylus radius | 10 µm ±1 µm |

| Measuring force of stylus | ≤ 0.016 N |

| Sensor guide pressure | ≤ 0.5 N |

| Battery | One 1.5V AA dry battery |

| Size | 73 x 28 x 62 mm |

| Weight | 220 g |

| Working Condition | Temperature: 0°C ~ 40°C |

| Relative humidity: <90% | |

| No vibration and corrosive medium around |

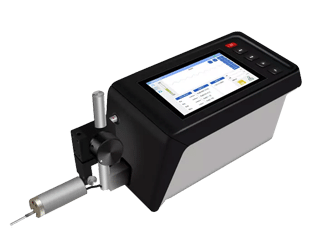

iSurfa-300 Roughness waviness tester

Features:

• High precision large stroke guide rail, length up to 50 mm.

• Sensor range ± 500 μm.

• The all-in-one machine is convenient to carry and comfortable to operate.

• The parameters are comprehensive, including 5 measurement types and a variety of national standards.

• Skidless measurement for more realistic feedback on the morphology of machined surfaces.

• The stylus can be directly replaced,and the replacement operation is convenient, which can realize the measurement in different scenes.

• The sensor can be switched vertically or in the same direction with the guide rail at will, so the measurement of deep grooves can be made from the side without being limited by the depth of the stylus and groove.

• Metric and Imperial system available.

• Chinese interface and English interface available.

• Data storage is convenient and can be directly stored in the built-in memory of the machine.

• The analysis algorithm including multiple filter methods can be matched at will to meet the requirements.

• It supports automatic multiple calibration of standard blocks, so that the calibration error is greatly reduced.

Technical data:

| Range | X direction | 30 mm |

| Z direction | ±500 μm | |

| Resolution | X direction | 0.0016 μm / ±50 μm - 0.016 μm / ±500 μm |

| Driver | Straightness | 1 μm / 30 mm |

| Evaluation length | Sampling length x number of samples (sampling length has standard mode and custom mode) | |

| Measurement speed | 0.05 mm/s - 0.10 mm/s - 0.50 mm/s - 1.00 mm/s - 2.00 mm/s | |

| Return speed | 0.05 mm/s - 0.10 mm/s - 0.50 mm/s - 1.00 mm/s - 2.00 mm/s | |

| Sensor | Mode | Standard universal type |

| Sensor mode | Differential inductance | |

| Range | ± 500 μm | |

| Stylus | 5μmR diamond 90° | |

| Contact force of the stylus | 7.5 mN (adjustable) | |

| Power supply | AC 220 V ±10% - Built-in rechargeable battery (AC adapter charging) - 3 hours charging time | |

| Power consumption | About 30VA | |

| Size | Actuator: 350 x 116 x 146 mm | |