DOWNLOAD

Flaw detectors

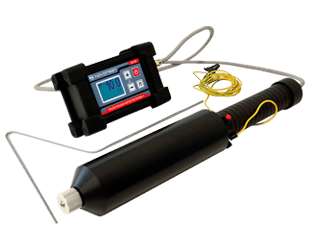

Ultrasonic flaw detector – UD2301

An ultrasonic flaw detector is designed to search for voids and inhomogeneities inside the materials under testing with ultrasound. It is the most common device in the world for non-destructive testing of metal (and other materials with low attenuation of ultrasonic waves) products in production, as well as objects in operation. Ultrasonic flaw detector UD2301 is a powerful, ergonomic, portable device that has all the functions of a general industrial ultrasonic flaw detectors and can be used in laboratories and workshops, and is perfect for field use. The device is supplied with PC software for uploading the measurement archive and processing the results.

Advantages:

• Superbright display with which it is comfortable to work outdoors on a sunny day.

• Frequency range from 0 to 10 MHz, with smooth adjustment.

• Display of a scale of scanning in microseconds and millimeters.

• Construction and processing A-scan and B-scan.

• The presence in the device of the operating mode of the DAC curves (construction of 16 points).

• Existence in the device of TVG mode (construction of 16 points).

• DGS function, with automatic calculation of the equivalent reflector size.

• Archive of measurements, settings, transducers with the ability to transfer data to a PC.

• Any side display orientation options that allow user to work in any position of the device.

• The device operates on standard AA batteries, as well as on conventional batteries, which makes them easy to replace.

• The UD2301 flaw detector can be powered by a universal mobile battery (power bank) via a mini USB connector.

• Ergonomic shockproof case with protective rubber protectors.

• Light weight and compact size.

Standard supply:

• Ultrasonic flaw detector

• UT-probes – 2 pcs

• Cable Lemo-Lemo – 1 pc

• AA batteries – 3 pcs

• Charger

• USB cable for PC connection

• Case

• Operating manual

Optional accessories:

• Couplant

• UT-probes

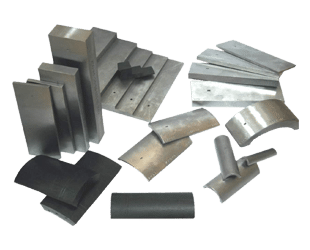

• Calibration blocks

Ultrasonic flaw detector – UD2303

Ultrasonic flaw detector UD2303 is a compact version of an industrial flaw detector with a set of functions and modes that are designed to simplify the routine process of product quality control as much as possible. Shock-resistant aluminum alloy case with a large battery will provide a long service life of the device and ability to be used in adverse conditions. UD2303 ultrasonic flaw detector has the function of screen rotation.

In other words, there is no need to hold the device in one position, since by pressing the button you change the position of the screen relative to the device, horizontally or vertically. Also, thanks to this feature, device is suitable for left-handed and right-handed people.

Features:

Device is designed to control the quality of products made of various materials, including: metal, plastic, glass, composite materials and etc. Device functions provided are checking the continuity of materials and identifying places of inconsistency, search for hidden corrosion, cracks and other internal defects by above listed materials. Ultrasonic flaw detector provides thickness measuring of various products, structures and it is able to perform inspection of welded seams, which would be useful both at the intermediate stages of production and the incoming inspection of semi-finished products.

Advantages:

• Automatic calibration.

• Intuitive device menu.

• Adjustable excitation pulse generator.

• Saving measurement results and ability to viewing.

• Transfer of archived records to PC.

Standard supply:

• Ultrasonic flaw detector

• UT-probes – 2 pcs

• Cable Lemo-Lemo – 1 pc

• Charger

• USB cable for PC connection

• PC program ( available from site download)

• Case

• Operating manual

Optional accessories:

• Additional probes (UT) and cables

• Standard calibration blocks

• Custom calibration blocks

• Couplant (gel)