DOWNLOAD

Bending coating testers

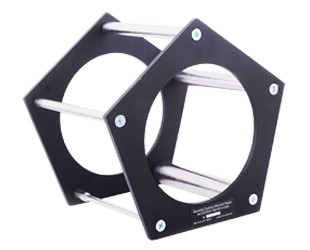

Bending coating tester

The bending coating tester measures the elasticity and the flexural strength of coatings through rounding the test sample on the set of cylindrical rods, which diameters are from 6 mm to 25 mm.

The instrument complies with ISO 1519-73, which extends to coating materials and sets the definition method of elasticity of the film at a bend. The method consists in the determination of the minimum diameter of the cylindrical metal rod that, after bending around it the painted metal plate, does not cause any mechanical destruction or de-lamination of single- or multi-layer paint film (ISO 1519, DIN 53 152).

Application:

It is recommended to use painted tin plate for testing. Tin has to have a smooth surface without any voids, rusty spots, and impurity.

The test samples are rectangular plate with 100 – 150 mm length and 20 – 50 mm width, which are made of black polished tin sheets 0.25 – 0.32 mm of thickness, or aluminum sheets and strips 0.25 – 0.30 mm thick, with single-layer or multi-layer paint film on them.

The method of applying the paint on the material, the thickness of film, the number of layers, the conditions and time of drying and the exposure of the film before the test, must be specified in the specifications and technical documentation of the test material. Before testing the samples are withstand at the conditions which are specified in the specifications and technical documentation of the testing material. The time and degree of drying is determined in compliance with ISO 1519, DIN 53 152.

The thickness value of tested paint film applied to the plate can be measured with coating thickness gauges, for example TP-2020. The tin plate (coated side to outside) is put on the rod with maximum diameter (25 mm), pressed tightly to the rod and smoothly bend it within 1 – 2 sec for 180° around the rod. After that, coating layer has to be analysed at the bend-place using a magnifying glass with 4-fold zoom looking for cracks and delamination.

If defects are absent, user has to continue bend the plate, but each time in a different location, successively from larger to smaller diameter of the rod, until the defects mentioned above are detected. If the specifications and technical documentation to the painting material stipulate the value of elasticity (rod diameter), the test is carried out using only the rod of this diameter. The result is the minimum diameter of the rod in millimetres that causes no destruction when testing the paint film.

Evaluation of the elasticity value of the film through the bending on a metal rod takes three tests of plates on the same rod.

Standard supply:

• Instrument

• Case

• Operating manual

Optional accessories:

It is possible to produce other diameters and lengths of test rods according to user requirements.

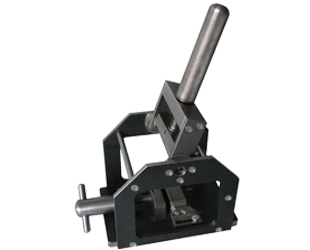

Cylindrical bending coating tester

The cylindrical bending coating tester allows to measure the elasticity and strength of coatings through bending the metal plate with tested coating applied around a set of cylindrical rods with diameters from 2 mm to 32 mm (other diameters on request). The device complies with ISO 1519-73 and specifies a method for determining the elasticity of the film during bending.

Operation:

The method consists in the determination of the minimum diameter of the cylindrical metal rod that, after bending around it the painted metal plate, does not cause any mechanical destruction or delamination of single- or multi-layer paint film (ISO 1519, DIN 53 152). The flexibility value of the coating with a certain film thickness is the smallest diameter of rod, when cracking does not occur.

The cylindrical bending coating tester consists of the frame with fixed clamps for tested samples and a special mechanism for rounding plates around the rod with different diameters. Pre-prepared tested sample is placed between the clamps and secured by rotating the handle. After that, push the tested object to the top of rod by rotating the handle and bending the plate around the rod.

Advantages:

The cylindrical bending coating tester, compared to other bend testers for coatings, allows to bend with a clearly predetermined gap (or without any gap) around the rod without deviation from the perpendicular and minimizes the impact of human factors on testing accuracy.

Standard supply:

• Instrument

• Case

• Operating manual

Optional accessories:

It is possible to produce other diameters and lengths of test rods according to user requirements.