DOWNLOAD

Adhesion testers

Tensile adhesion tester

Adhesion is the tendency of dissimilar particles or surfaces to cling to one another. In the field of quality testing, adhesion of coatings to the base material, such as paints, plastic, epoxy mixtures, sprayed metal, laminate to wood and other metal and polymer coatings, is the most often measured.

Tensile adhesion tester AC-1 is a pull-off type adhesion tester for determining the adhesion strength in MPa and can be used in compliance with EN13144, ISO4624 and ISO16276-1.

Operation:

To determine coating adhesion, using the tensile adhesion tester, requires:

1. Glue the dolly to the coating with glue (epoxy, cyacrine or other, depending on the coating).

2. Using a special cutter, cut through the coating to limit the tested area from the main layer.

3. After the glue is frozen, attach the adhesion tester to the dolly tightly, and turn the main screw of the device until the dolly with the coating comes off the base.

4. Record the MPa value on the scale of the device in accordance with the dollies used.

Advantages:

• Simple design and easy to operate.

• Result in mPa values.

• Universal in use.

Optional accessories:

• Dollies

• Holesaw (cutter) for cutting area of testing

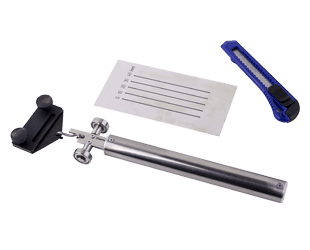

Standard supply:

• Adhesion tester

• Dollies: n° 1, n° 2 – 3 pcs

• Holesaw (cutter) for cutting area of testing

• Wrench

• Case

• Operating manual

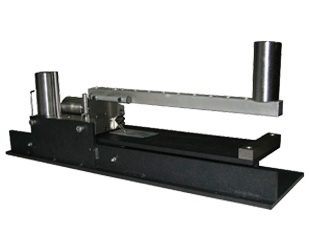

Peel adhesion tester

Adhesion tester AP-1M is designed to measure the adhesive strength value of the coatings on different structures, as well as to determine the adhesion value of polymeric insulating tapes which are generally used for pipes insulation. Adhesion tester AP-1M is reliable and easy in operation.

Features:

Adhesion tester AP-1M consists of a body with removable clamp for holding the peelable strip of tested material with built-in dynamo-meter where breakout force is displayed. The design of the instrument allows user to set (control) the angle of peeling.

The dynamo-meter’s scale is applied to pull the rod, so that its usability significantly improves, compared to existing analogues: user’s hand never overrides the scale of the instrument. Adhesion tester has reliable construction of stainless steel, that guarantees its long life. The design of the instrument allows user to operate at low temperatures or conditions of high humidity and dust.

Standard supply:

• Adhesion tester

• Knife

• Template for incision

• Operating manual

Optional accessories:

• Knife

• Template for incision