GMM Gear Measuring Machines series

The GMM gear measuring machines series, thanks to customizable software packets for different applications, is suitable for performing a wide range of measurements in a completely automatic way. It is a metrological multifunctional system which is able to recognise and carry out the most frequent measuring software processes in the industrial sector. The structure is made of three linear coordinate axes with pneumostatic support on granite tracks, that totally delete any friction and wear.

The placement of two tailstocks is provided, one of that is integral with the rotary axis (W) and the other one is opposite and height adjustable, mounted on a specific granite column. The control of the tailstock is motorised.

This four-axes coordinate system is fitted for the placement of an analog measuring head which, with the use of a tracer, physically touches the sample’s surface and tests the theoretical trend, made by a suitable interpolation created by the test, on the basis of the mathematic formulation implemented in software.

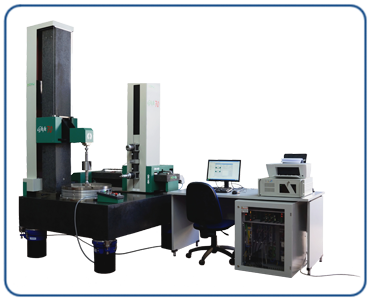

Gear measuring machine GMM 40 – Small Size

IT MEASURES GEARS WITH OUTER DIAMETER UP TO 400 mm

It is a machine with high-level dynamic features thanks to the use of linear motors with pneumostatic supported tracks, which allow movement without any friction.

The structure includes three linear axes (X, Y, Z), a rotary axis (W) and a tailstock column, everything based on high-accuracy granite tracks. This permits a better long-term stability and a low thermodynamic response, even in case of temperature variation.

Gear measuring machine GMM 70 – Medium Size

IT MEASURES GEARS WITH OUTER DIAMETER UP TO 700 mm

Even though GMM 70 maintained the same construction principles, compared to the Small Size model, it has been created to allow to measure heavier and bigger samples with very high accuracy.

The structure lies on the floor with pneumatic autolevelling supports. This ensures that the whole measuring system is isolated from external stresses and that the kinetic energy of moving masses is absorbed. The rotary table is built in order to sustain a load of about 1500 kg thanks to the pneumostatic support on granite track.

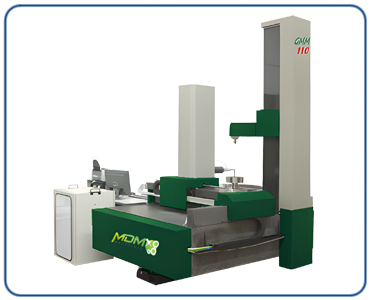

Gear measuring machine GMM 110 – Big Size

IT MEASURES GEARS WITH OUTER DIAMETER UP TO 1100 mm

GMM 110 is the larger model of the series and it has been sized and designed in order to be able to measure very big and heavy gears and other parts with high accuracy.

The structure is totally made of granite without any welded part. The sturdy rotary table, with a considerable diameter, lies on pneumostatic support tracks, and it is moved by an electronic axis and a next-generation encoder.

It can bear loads up to 2000 kg, maintaining a resolution of 0.36” of arc (3,600,000 counts per lap), thanks to a special torque motor with a big diameter and without using any type of mechanical reduction (electronic shaft).