DOWNLOAD

Other non-destructive testing instruments

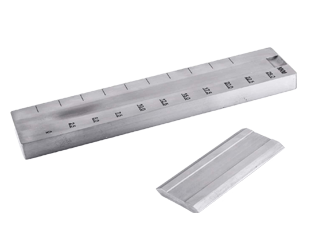

Grindometer

The high precision grindometer GD-1 has a single groove.

Grind gauges are used to determine particle size and fineness of grind. The tested materials are paints, chocolates, inks, coating materials and so on.

The device is made of hardened stainless steel. The scale on the top of the device is graduated in micrometers.

STANDARDS:

ASTM D 1210, AS/NZS 1580.204.1, DIN 53203, EN 21524, FTMS 141 4411.1, ISO 1524, JIS K 5600-2-5, NF T30-046

Standard supply:

• Stainless steel block

• Precision ground scraper

• Carrying case

Optional accessories:

The instrument is available in four versions with different measurement ranges:

• 0 – 25 µm

• 0 – 50 µm

• 0 – 100 µm

• 0 – 150 µm

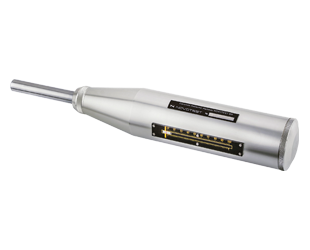

Digital surface profile gauge

Digital Surface Profile Gauge NOVOTEST SP-1M is designed for profile measuring on either flat or curved surfaces. Also it can be used for measurements of surface roughness (Rz), after abrasive blasting pre-painting work.

The electronic unit is the same as Coating Thickness Gauge NOVOTEST TP-1M. NOVOTEST SP-1M consists of electronic block of Coating Thickness Gauge NOVOTEST TP-1M and probe DSH.

Standard supply:

• Electronic unit TP-1M

• Probe DSH – 1 pc

• Set of reference samples

• Batteries AA – 2 pcs

• Charger

• Carrying case

• Operating manual

Optional accessories:

• Additional probes

• Batteries

• Charger

• Set of reference samples